Diecutting is a process that stamps a shape out of cardboard or paper. It’s incredibly useful for making things like cardboard boxes or packaging, but can also make a business card or a flyer much more interesting by diecutting the piece to a custom shape rather than just a plain old rectangle or square.

Like most things, the process starts with your design. Indesign is the best software to use (don’t be tempted to use Photoshop, Word, Publisher or Powerpoint, they simply don’t have the functionality you need to make a proper print-ready file). Let’s cover off some terminology first though, to make sure we’re understanding the process.

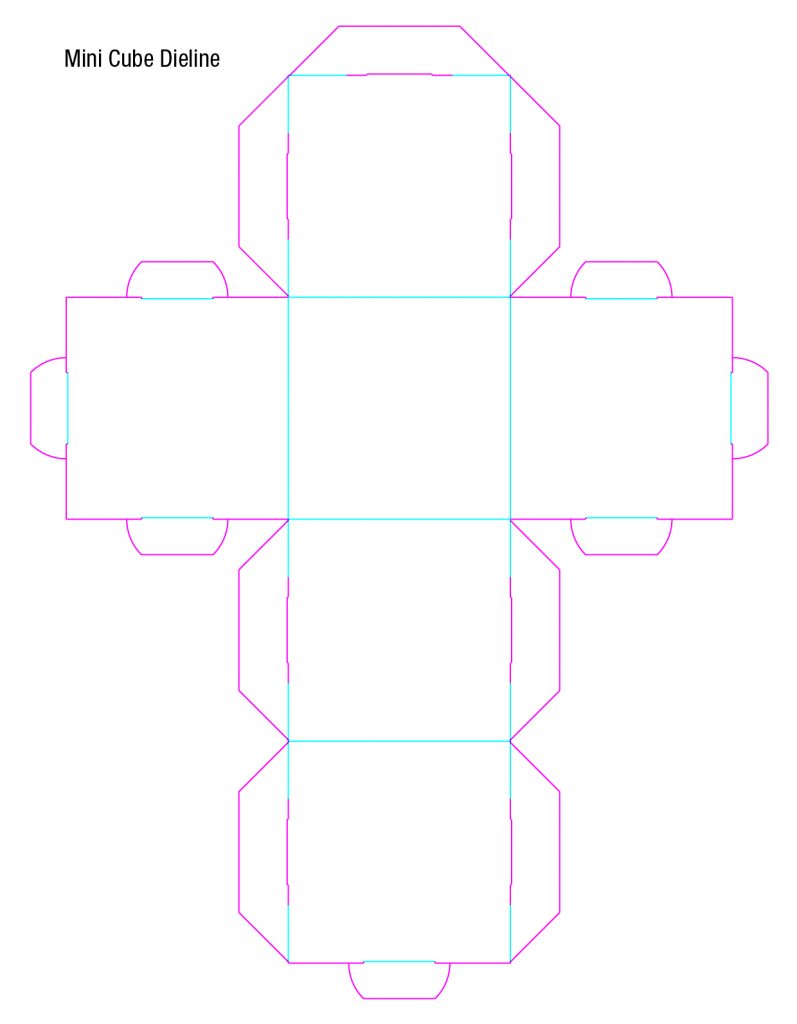

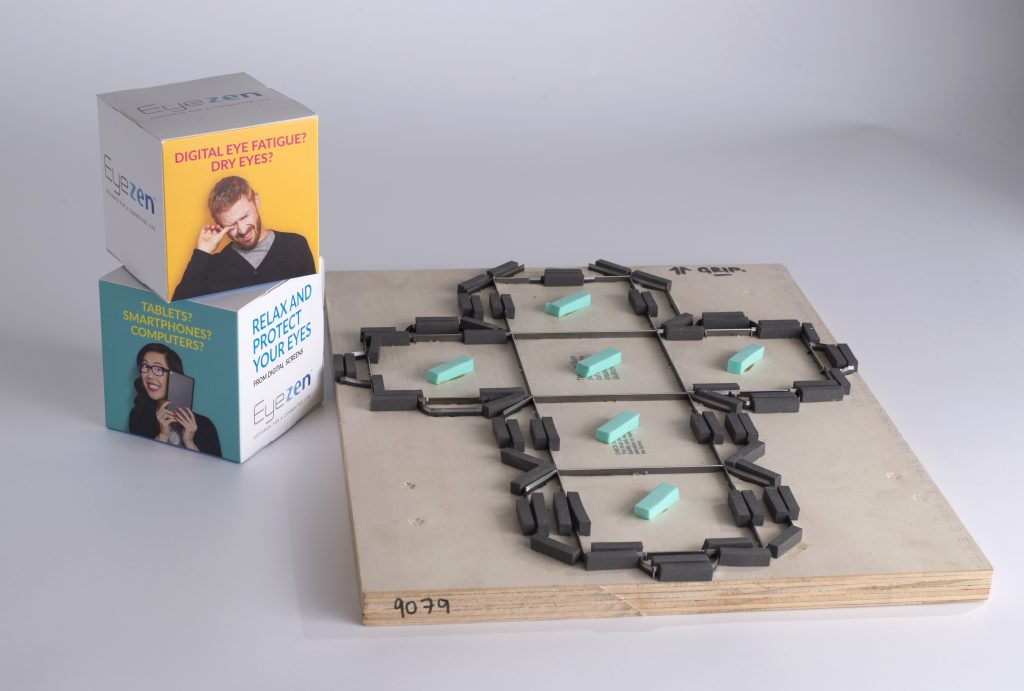

What you see in this image to the below left, is a ‘dieline’. It’s the plan or map of the shape that you’re piece is going to end up as. The image on the right is the cutting forme that we make from that dieline. The way you create a dieline is very important, and very specific, which is why you use Indesign.

I’m going to very briefly lead you through the process of creating a dieline in Indesign. Within your Indesign layout, go into your colour swatches and create a new spot colour and name it “cutline”. Now give this cutline a representational fill of 100% magenta. Then create a second spot colour, call it “creaseline” and give it a representational fill of 100% cyan. If you are likely to have any perforations in your design, create a third spot colour called “perforation” and give it a representational fill of 100% yellow (these representational fills can be changed to suit your preferences). Collectively, these lines are what we call your ‘dieline’. Now start drawing shapes using either your cutline, creaseline or perforation as your outline colour. Some people only make a colour called ‘cutline’ and then when they want to do a crease, they show it as a dotted line, made up out of the cutline colour – don’t be that guy – that will just give you a rather clumsy perforation instead of a crease, and your diemaker will be wondering “Do they really want a perforation or do they want a crease?” Do it the right way and then everyone knows what you want, and you’ll get a great result. Your design is going to incorporate both the printed elements of your design (the part that is printed in ink) and the dieline. Your dieline should be sitting on the top of your underlying artwork, so any text, images and elements that are to be printed will be sitting under the dieline. Make sure that you include bleed where ever your design has background colour that bleeds off the edge – 3mm past the edge of the dieline. Once you’ve drawn your design with all the dieline elements in place, one very important step is to select all components of the dieline and set them to overprint. (Window> Output> Attributes> Overprint Stroke). The reason this is important is because we’re going to turn off your dieline colours when we come to print your underlying design, and if you haven’t set your dieline to overprint, the dieline will ‘knock out’ where ever the dieline goes over the top of your design, resulting in unsightly white lines right on the cut or creaselines. Once your design is complete, you output to a pdf and send that to us. What we then do, is we extract the dieline from your pdf and we send that to our diemaker. He very carefully bends pieces of steel cutting rule, perforation rule and creasing rule in the shape of your dieline. He then takes a block of plywood and cuts the outline shapes with a jig saw into the wood, and then he inserts the steel rules into the slots in the plywood. The result is a cutting forme, an example of which is pictured here. This particular photo shows little strips of rubber mounted around the steel rules, this helps the printed sheets spring away from the steel rules after the sheet has been pressed against the rules. Also pictured is the end result of the cubes that were made from this particular cutting forme. So… a dieline is what you draw to show our diemaker how to make your cutting forme. Easy! Now lets look at the machine that cuts the paper or cardboard to shape. First though, we start off by printing your underlying design on our digital press. To begin with we send two versions of your design to our press – one with the dieline on and one with the dieline switched off. We print your required quantity of sheets (plus a few extras just in case) with the dieline switched off, and then we print about 20 or 30 sheets of the version with the dieline switched on and we use these as our ‘make-ready’ copies – in other words, these are the sheets we use to set up the machine that will cut the shapes – it shows us where the cut lines should hit the sheet. As we set the machine up for diecutting, we feed through the sheets with the dieline on and we juggle the position of the cutting forme till the cut and crease lines are hitting exactly on top of the printed image of the dieline. By the time we’re all set up, we’re ready to start running the sheets without the printed dieline.

The machine that does the cutting is a 1965 Heidelberg Platen (letterpress machine) and the sheets of paper are fed between a chase (the part that holds the cutting forme) and the platen (the part that presses up against the chase). Each sheet is fed one at a time between the chase and platen, as the platen opens and closes at speed, with metal arms that grip the paper and whip each sheet in and out of the platen.

If you don’t want to make a dieline from scratch, you can visit our Dieline Library, or search the web for dielines other people have made already. Although, if you find a dieline in our library that you like, there’ll already be a cutting forme that you can borrow (if you’re printing and diecutting your job with us), which will save a lot of money since you won’t have to pay to have a new cutting forme made.